Logistics / Transportation

Durable Identification for Transportation Applications

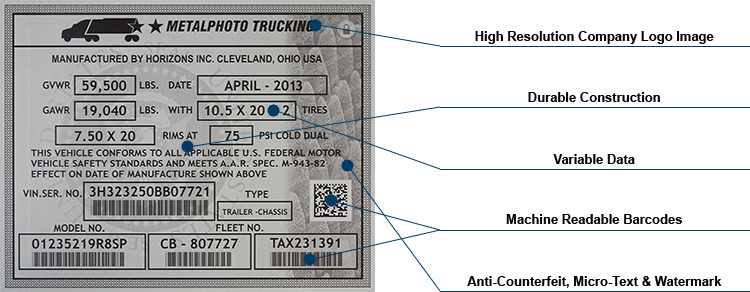

The Intelligent Metalphoto® VIN Tag replaces traditional etched plates because of greater durability and optional machine-readable barcodes. Those features create the following benefits for trailer manufacturers and their customers:

Benefits to the Trailer Manufacturer

- Drive aftermarket revenue: the Intelligent Metalphoto® VIN Tag digitally links to sources for OEM aftermarket parts and service.

- Enhance your selling proposition: the Intelligent Metalphoto® VIN Tag differentiates your trailer from competitors and offers your customers a series of cost-saving benefits.

- Enhance your brand image: the Intelligent Metalphoto® VIN Tag can contain a crisp, high-resolution brand logo image that lasts the life of your trailer – demonstrating the quality of your brand.

Benefits to the Fleet Owner

- Asset Tracking: the Intelligent Metalphoto® VIN Tag ends manual data entry with an asset-specific barcode – reducing labor and errors associated with trailer intake at transfer stations and maintenance facilities.

- Asset Maintenance: the Intelligent Metalphoto® VIN Tag gives the operator and mechanic a service history for each trailer – helping to locate OEM-approved replacement parts and reduce downtime through targeted preventative maintenance.

- Little to No Replacement Costs: the Intelligent Metalphoto® VIN Tag’s durability comes from its image which is sealed inside of the anodized aluminum, providing resistance to road-salt corrosion, abrasion and other conditions that can obscure traditional etched steel plates.

- Proven Track Record: used by several leading trailer manufacturers already, the Intelligent Metalphoto® VIN Tag is already being deployed by leaders in the industry.

Applications

Several leading manufacturers of trailers, ISO shipping containers, tankers, chassis and auto-haulers have converted their etched plates to Metalphoto® VIN Tags including:

Feature Overview

Here’s How It Works

Durability:

The Intelligent Metalphoto® VIN Tag’s durability comes from Metalphoto’s photographic image which is sealed inside of the anodized aluminum, providing resistance to:

- Sunlight degradation (20+ years)

- Road-salt corrosion (30 days in chamber)

- Abrasion (7,000 cycles on tabor abrader)

- High temperatures (1,000°F)

- Chemical exposure (diesel fuel, hydraulic fluid and several others)

Resolution:

The Intelligent Metalphoto® VIN Tag supports variable data and barcodes because it is a photographic technology. That means:

- Variable data can be embedded in the plate or punched/scribed your location(s)

- Barcodes reduce data entry errors and time – helping your customer track and maintain your product

- Optional two-dimensional QR code can link mechanics to a maintenance history and parts list of OEM-approved aftermarket parts

- Optional anti-counterfeit features such as watermark and micro-print verify authenticity of your product

In addition to VIN Tags, manufactures use Metalphoto for these permeant identification items:

- CSC Safety Approval Plates

- ISO 6346/BIC intermodal shipping container nameplates

- And other durable nameplates, maintenance schematics and labels